Disc Diffusers 260 MM

The Fine Bubble Disc Diffuser are designed with an arch surface so that there is minimum accumulation of MLSS and debris on the surface.

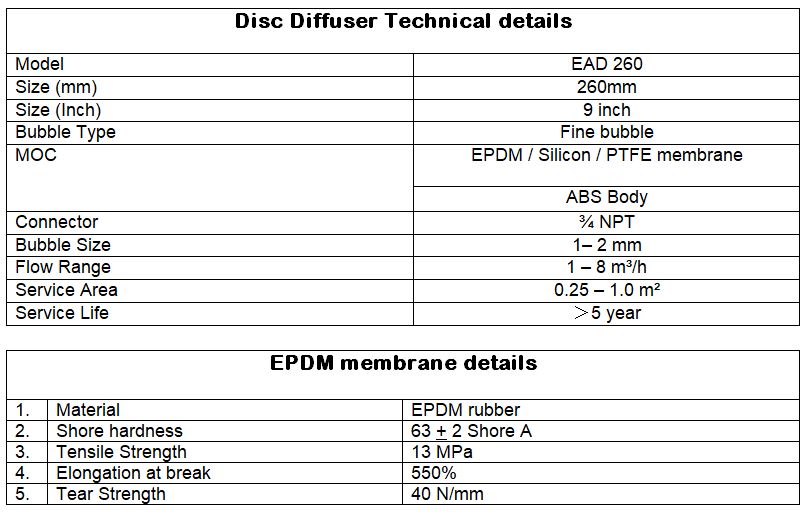

The main body is made of ABS (engineering plastic). The membrane is made of high quality EPDM rubber with anti-corrosion surface. The rubber membrane perforation is made with high precision. A check valve device is given at the bottom of the disc diffuser to prevent the mixture from entering the distribution network system and blocking the air lines.

The diffusers have excellent physical and chemical properties. The diaphragm shrinkage is minimal, hardening due to aging is least in comparison.

Disc Diffuser Design advantages

Precision Die Cut Openings

For optimum performance and efficiency, fine bubble disc diffuser offers accuracy when it comes to its die cut openings. A high oxygen transfer obtained through its adjustable operating pressure based on the client’s specifications. Several slit patterns vary according to number, length, and spacing.

Active Diameter

Fine bubble disc diffuser comes in active diameter of 215 mm to 300 mm. With the new style aerator diameter these aerators are more effective than their conventional counterparts. Energy consumption is also reduced.

Standard Membrane Materials

The fine bubble, disc diffuser are designed for a plethora of applications. The EPDM technology specifically provides reliable solution for municipal wastewater, Beverage and food processing units. Silicone membrane diffuser is specifically used for refining processes, petrochemicals, and the paper industry.

Anti-fouling Surface for Membrane Materials

Relatively based on the latest Nano technology, the surface of the membrane material is meant to prevent accumulation of both biological and solids encrustations.

Reinforced Polypropylene Body Plate and Ring

Disc diffusers are strengthened with glass fibre for optimum chemical resistance. It can also endure varying temperatures and resist harmful UV rays.

Safe and Secure Non – return Valve

All fine bubble disc diffusers come with built-in non-return valves to ensure safety and security of the water treatment process. This valve controls the build-up of sludge and prevents its infiltration into the aeration system, especially when the airflow is sporadic.