Fine Bubble Tube Diffusers

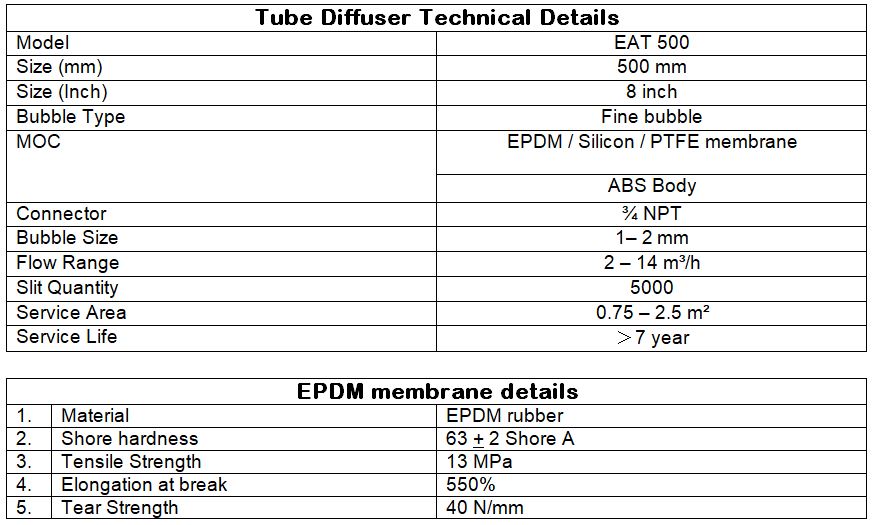

Tube diffuser consists of threaded 3/4″ NPT (male) inlet, diffuser body, Flexible EPDM membrane media, membrane retainer clamps, check valve system, with air inlet orifice on tube body and precision die cut perforations for fine bubble aeration.

EPDM aeration diaphragm is manufactured by compression molding and cured as per standard practice. The rubber has very little plasticizer content. The perforation on the membrane surface is 1 mm to 2 mm.

The ABS body is made by compression molding with modern equipment utilizing individual thermocouples and vacuum technology ensuring high product strength and quality.

The diffusers have excellent physical and chemical properties. The diaphragm shrinkage is minimal, hardening due to aging is least in comparison.

Main features

- The composite diaphragm has a long service life of 5 – 8 years, high oxygen efficiency.

- High power efficiency and low energy consumption, saving about 30% of the operating cost compared with ordinary tube diffusers.

- Anti-clogging, corrosion resistant.

- Ease of installation (As little as two minutes per diffuser).

- Maintenance-free design, unique air distribution structure providing uniform air distribution.